CASE STUDY

Telecom mast cabinet

Most of us will have walked past one of these cabinets, whether it’s popping to the post box or walking the dog, however you probably didn’t even notice!

These cabinets are in fact enclosures that wrap around a structure, a telephone mobile mast in this case, to house equipment and cabling for the structure. This telecoms metal enclosure is made from pieces of stainless steel with a powder coated finish.

CAD design

Client A provided all the drawings and instructions for the enclosure. Constant’s team of CAD engineers imported the CAD files and aligned them for our machines and procedures, to give the most efficient manufacturing process for the enclosure.

The enclosures are constructed from several sheets of special grade stainless steel at 1.5mm thick.

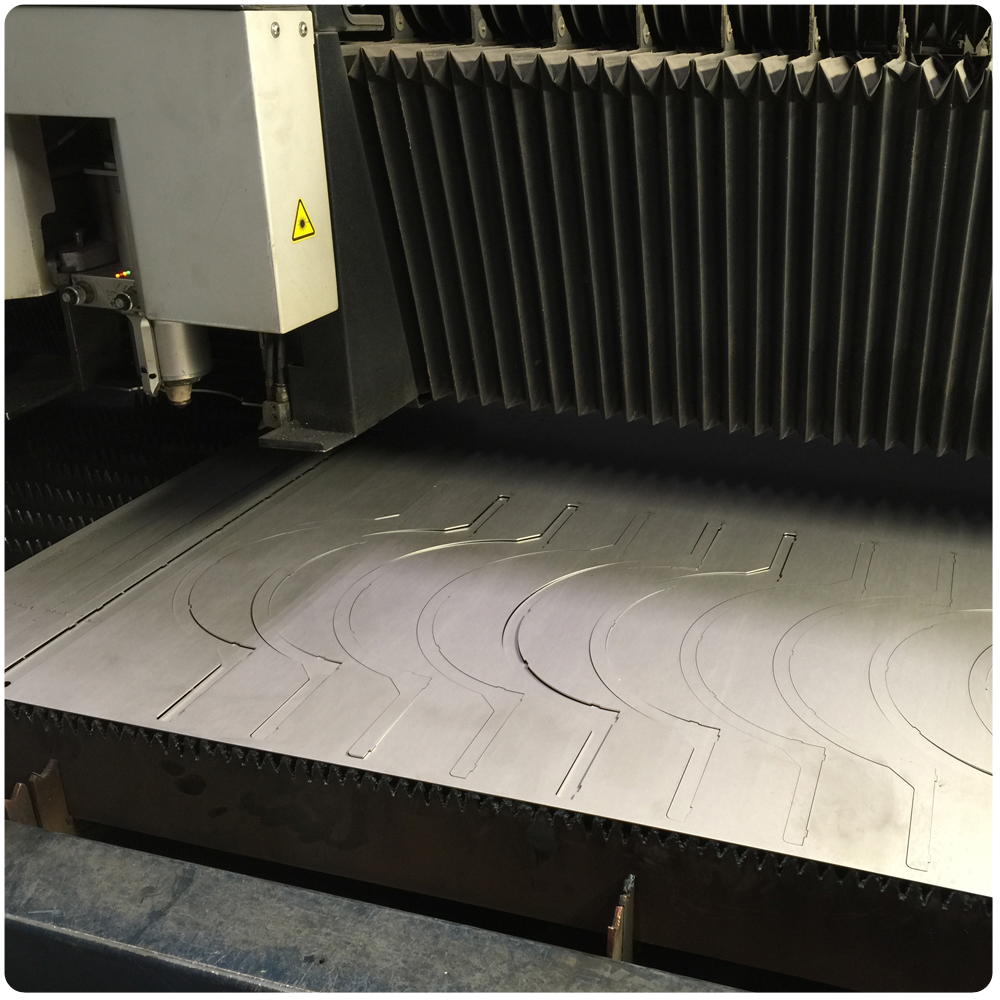

Punch and laser cut

The phone mast’s enclosure main body was cut on our Trumpf TruPunch 3000, and the secondary parts such as internal pieces and the top hood were cut on our laser machine.

Having a range of machines at Constant allows us the flexibility to use different machines for different parts, producing the best and most cost effective method of manufacturing for the project at hand.

Press brake

Up next is the bending phase on the press brakes. The metal enclosures are quiet large, so long resting braces are used to prevent the pieces warping and aid the operator in performing the bends. You can see them extruding out from the press brake.

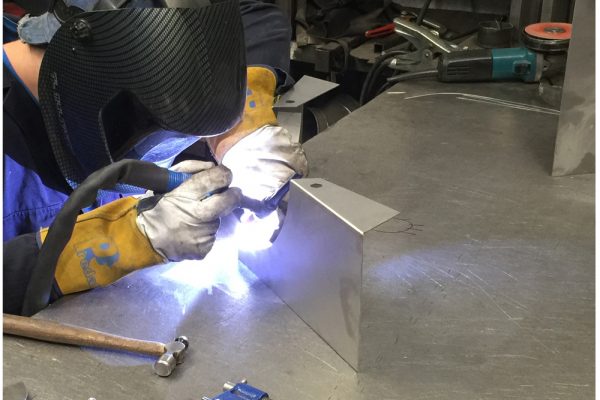

Welding

All the pieces are combined together with one of our welders. Firstly he tacks the hood roof pieces together, somewhat like pinning a piece of clothing before using a sewing machine. See photo and video clip below.

Then he secures the main body of the telecoms enclosure together with a bracing clamp, and begins to tack the arc shape roof onto the main unit.

Once the unit has been tack welded together, the welder proceeds to TIG weld the enclosure’s side and roof sealing the unit.

Finishing

Next the team get to work smoothing down the edges, grinding and linising to give the best surface for the end product and for the powder coating to adhere too.

The metal cabinets are now finished off, and polished down ready, to go to powder coating department.

Powder coating

As this cabinet has several captive nuts for assembly, we plug them with small ultra bake caps/plugs, in the industry known as ‘noggings’. This prevents any paint build up in the threads during the powder coating process.

The telecom cabinets are hung on the powder coating line and go through the pre-treatment line to remove any dust or grease on the metal, and then make their way through the drying ovens to be spot on for the paint process.

Assembly

Once the enclosures are cool, it’s off to assembly. We painted several colours for our clients, including green, brown, grey and blue. The finished colours are designed to blend into backgrounds such as nature reserves, housing complexes or town centres. This contract is classed as a ‘full assembly contract and packing’ job. This means we have been provided with, or sourced, parts to add into the cabinet when assembling. This includes cables, labels, customer branding and customer branded hinges.

Final product

The customer attaches their own locking mechanism when they install their electrical components inside and place on site. This unit is designed to fit around a telephone mast/mobile phone mast and reduce the amount of ground space used up by metal cabinets on pavements and path ways.

The unit fits snugly around the mobile phone pole, so working closely with the client is pivotal at the design stage to produce a perfect fit product in the assembly stage.